RXR-MC80BD

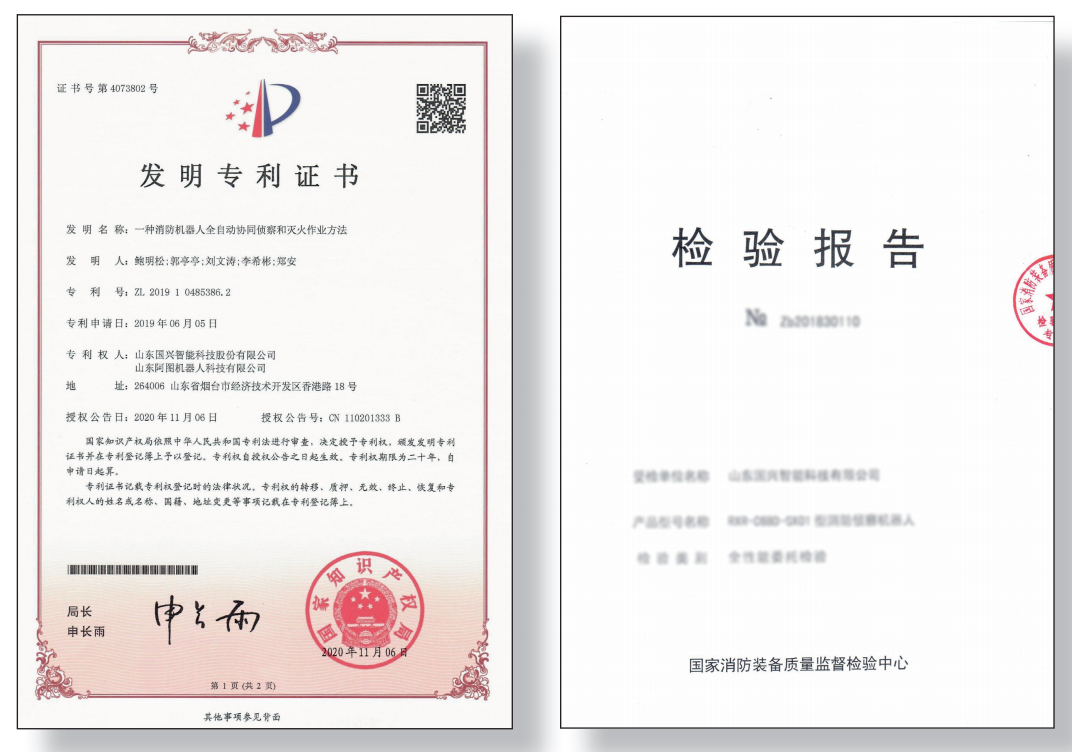

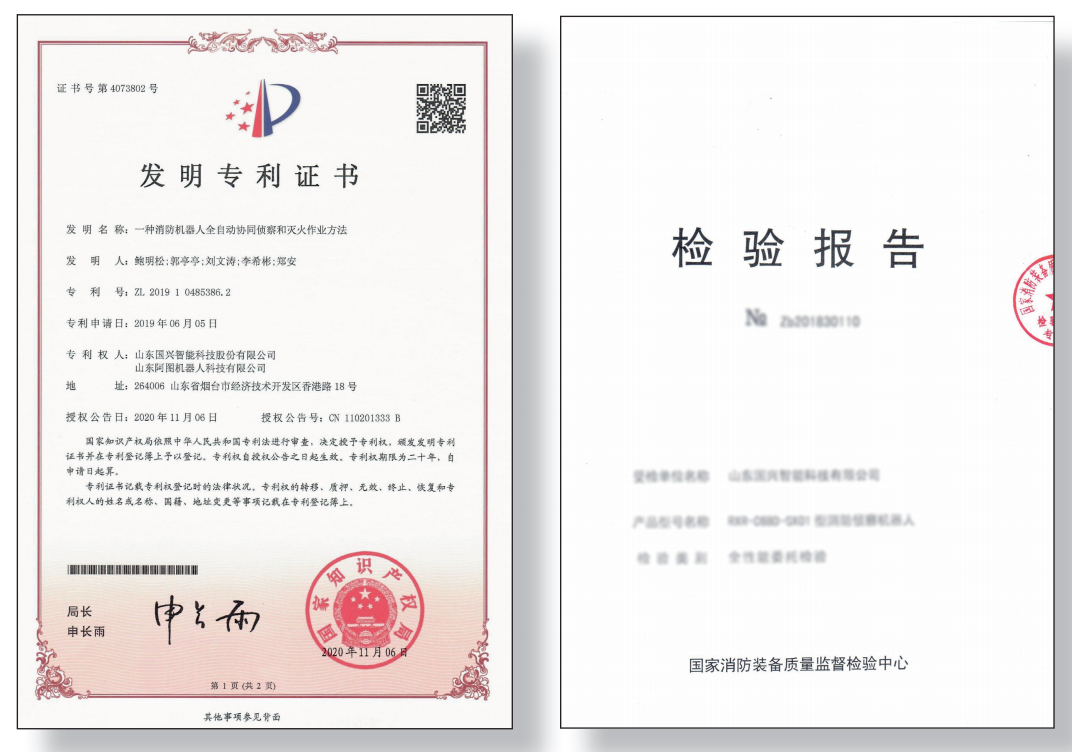

is designed and produced according to GB3836-2010 explosion-proof standard.

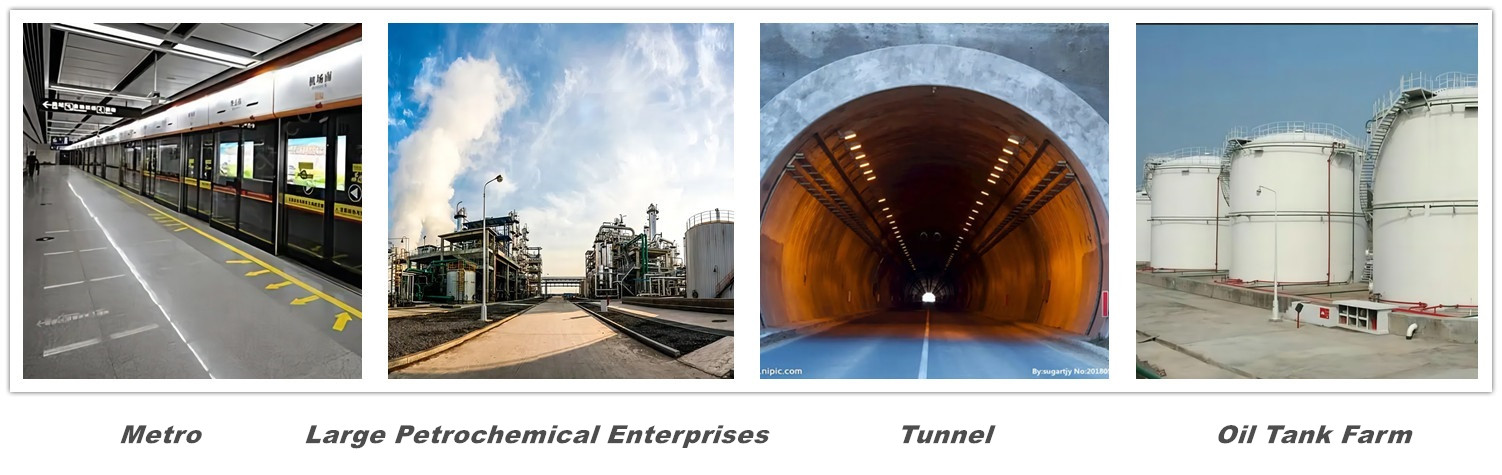

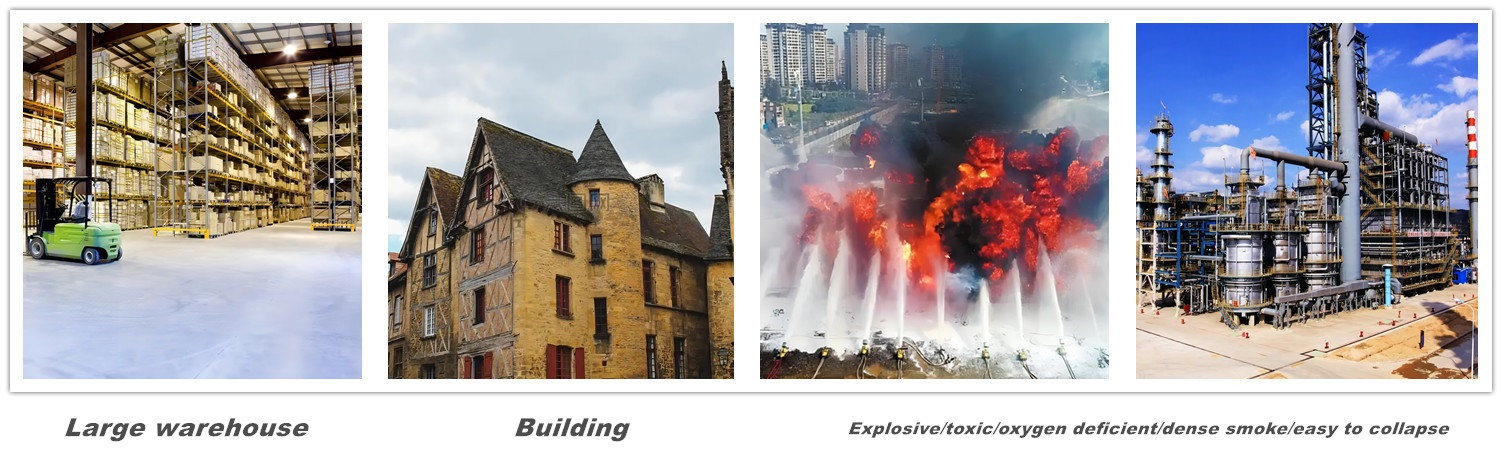

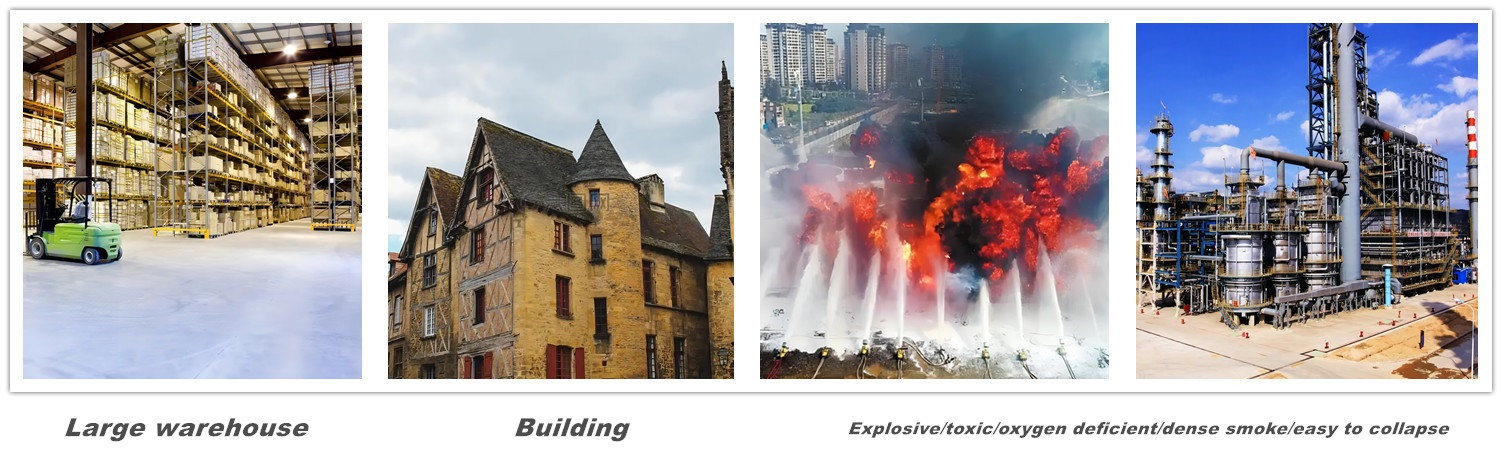

It can replace fire and rescue personnel to enter the scene of inflammable, toxic, hypoxia, smoke and other dangerous disasters and accidents for fire fighting, effectively solve the personal safety of fire personnel in the above places. Simple body design, more stable, with high power DC deceleration motor to make obstacles become particularly simple.

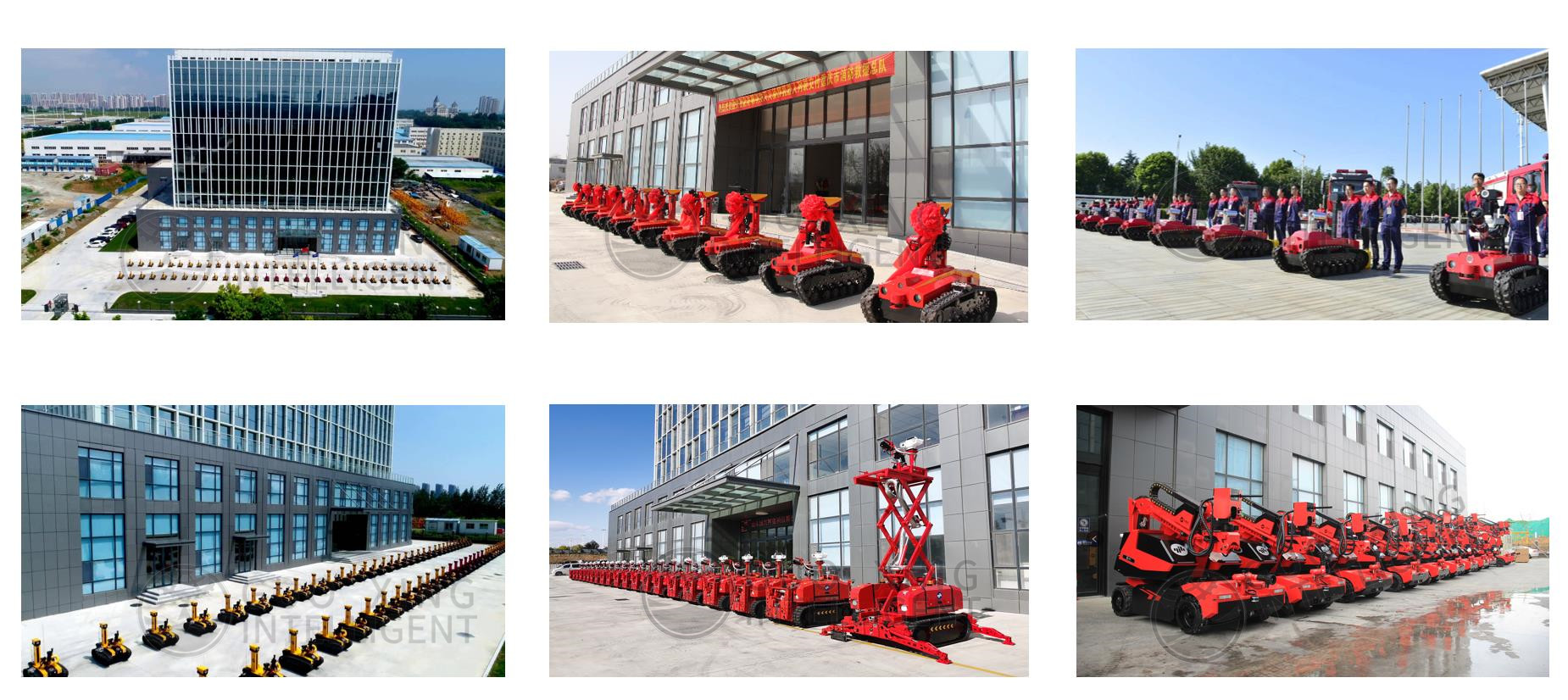

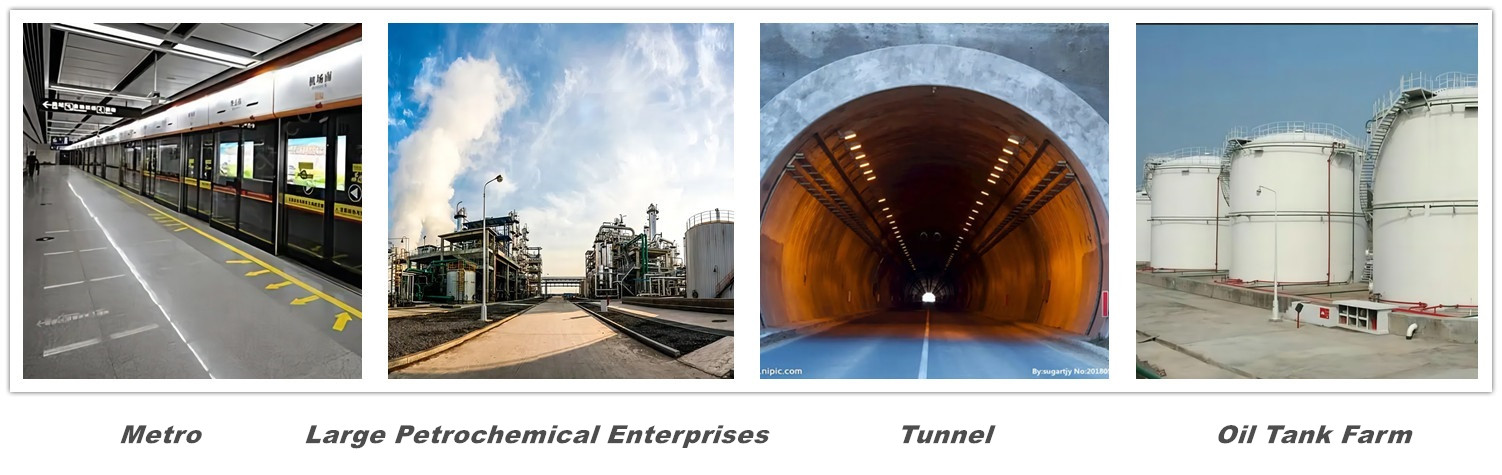

In the dynamic and hazardous environment of oil and gas facilities, fire safety is a paramount concern. Fires can escalate rapidly, posing serious risks to human lives, critical infrastructure, and the environment. To address this challenge, explosion-proof firefighting robots have emerged as a revolutionary solution, offering significant advantages in fire suppression. This article explores the key benefits of employing explosion-proof robots in oil and gas facilities to enhance fire safety and protect valuable assets.

Swift and Targeted Response: Explosion-proof robots are equipped with advanced sensors and navigation systems, enabling them to swiftly identify fire hotspots and respond promptly to emergent situations. With precise targeting, these robots can direct firefighting efforts to the most critical areas, preventing the spread of fires and limiting potential damage.

Minimizing Human Exposure to Hazards: Oil and gas facilities often contain flammable substances, making firefighting operations dangerous for human responders. By deploying explosion-proof robots, companies can reduce human exposure to these hazards, protecting firefighters from potential injuries and ensuring their safety during critical firefighting operations.

Remote Operation Capabilities: The remote operation feature of explosion-proof robots is a game-changer in fire suppression. Operators can control the robots from a safe distance, accessing real-time data and making informed decisions on firefighting strategies. This remote functionality ensures that firefighting efforts can begin immediately without waiting for human responders to reach the site.

Resistance to Explosive Environments: One of the most significant advantages of explosion-proof robots is their ability to function safely in hazardous and explosive environments. These robots are built with specialized materials and components to prevent sparks or ignition sources, enabling them to operate in the presence of flammable gases and materials without risk of causing additional explosions.

Adapting to Challenging Terrain: Oil and gas facilities often feature complex structures, confined spaces, and challenging terrain. Explosion-proof robots are designed to navigate through such environments with ease, accessing areas that may be difficult for human responders to reach. This adaptability ensures comprehensive fire suppression coverage throughout the facility.

Continuous Monitoring and Real-Time Feedback: Explosion-proof robots continuously monitor the fire situation, providing real-time feedback to the operators and incident commanders. This data allows for timely adjustments to firefighting strategies, ensuring a proactive approach to fire suppression and preventing fires from escalating beyond control.

Conclusion: In the high-stakes world of oil and gas facilities, efficient fire suppression is critical to ensuring the safety of personnel and protecting valuable assets. Explosion-proof firefighting robots offer numerous advantages in this regard, from swift response and targeted fire control to reducing human exposure to hazards and adaptability in challenging terrain. By leveraging the benefits of explosion-proof robots, companies can enhance fire safety measures, minimize potential risks, and maintain the continuity of their operations in the face of fire emergencies.

Thermal Infrared Image Camera

TFT Fire Monitor: 80L/S flow, water/foam dual-purpose, range 80 meters

Gas collection: The collection of six gases around the robot body

Lighting: double LED strong lightAcoustic-optic

Alarm: the robot sends out acoustic-optic alarm under the running state of the robot body

Automatic obstacle avoidance: always detect obstacles in front to avoid collision

Spray cooling: water curtain spray cooling

| Chassis configuration parameters | |||

| Dimension | 1612*910*1427mm | Weight quality | 726kg |

| Max obstacle height | 》220mm | Climbing ability | >70% |

| Direct run deviation volume | 《5.1% | Speed | >1.5m/s |

| Infrared thermal imager | Yes | Braking distance | <0.15m |

| Anti-collision function | yes | Spray cooling device | yes |

| Lighting | yes | Acoustic-optical alarm function | yes |

| Wading depth | 400mm | Water-proof function | IP67, top IP65 |

| Drag water belt ability | 2pcs80water belt 100M | Working time | 5h |

| Remote distance | 1000m | Speed control way | Wireless control |

| Gas collection | O2/CO2/CO/H2S/CH4/NH3 6kinds of toxic and combustible gases | ||

| Fire water cannon configuration parameters | |||

| Working pressure | 1.0MPA | Flow | 80L/s |

| Fire range | Water>85M, foam>80M | Pitching angle | -18~90 degree |

| Rotary | -45 ~ +45 degree | ||

| Control box configuration parameters | |||

| Dimension | 467*366*188mm | Weight | <10kg |

| Display size | 15inch | Working pressure | 24VDC/12VDC |

| Digital transmission frequency | 902-928MHZ | Format | Portable |

| Camera configuration parameters | |||

| Working temperature | DC12V | Signal system | PAL or webcam |

| Average relative humidity | <95%(+25degree) | Cloud platfrom performance | initial height>1430mm, lift up the rear height>1940mm |

Please don't hesitate to send us message!

Contact us now!!

00001. Firefighting robot

00002. Fire robot

00003. Fire rescue robot

00004. Fire suppression robot

00005. Fire response robot

00006. Fire emergency robot

00007. Fire extinguishing robot

00008. Fire safety robot

00009. Fire service robot

00010. Firefighter robot

RXR-MC80BD

is designed and produced according to GB3836-2010 explosion-proof standard.

It can replace fire and rescue personnel to enter the scene of inflammable, toxic, hypoxia, smoke and other dangerous disasters and accidents for fire fighting, effectively solve the personal safety of fire personnel in the above places. Simple body design, more stable, with high power DC deceleration motor to make obstacles become particularly simple.

In the dynamic and hazardous environment of oil and gas facilities, fire safety is a paramount concern. Fires can escalate rapidly, posing serious risks to human lives, critical infrastructure, and the environment. To address this challenge, explosion-proof firefighting robots have emerged as a revolutionary solution, offering significant advantages in fire suppression. This article explores the key benefits of employing explosion-proof robots in oil and gas facilities to enhance fire safety and protect valuable assets.

Swift and Targeted Response: Explosion-proof robots are equipped with advanced sensors and navigation systems, enabling them to swiftly identify fire hotspots and respond promptly to emergent situations. With precise targeting, these robots can direct firefighting efforts to the most critical areas, preventing the spread of fires and limiting potential damage.

Minimizing Human Exposure to Hazards: Oil and gas facilities often contain flammable substances, making firefighting operations dangerous for human responders. By deploying explosion-proof robots, companies can reduce human exposure to these hazards, protecting firefighters from potential injuries and ensuring their safety during critical firefighting operations.

Remote Operation Capabilities: The remote operation feature of explosion-proof robots is a game-changer in fire suppression. Operators can control the robots from a safe distance, accessing real-time data and making informed decisions on firefighting strategies. This remote functionality ensures that firefighting efforts can begin immediately without waiting for human responders to reach the site.

Resistance to Explosive Environments: One of the most significant advantages of explosion-proof robots is their ability to function safely in hazardous and explosive environments. These robots are built with specialized materials and components to prevent sparks or ignition sources, enabling them to operate in the presence of flammable gases and materials without risk of causing additional explosions.

Adapting to Challenging Terrain: Oil and gas facilities often feature complex structures, confined spaces, and challenging terrain. Explosion-proof robots are designed to navigate through such environments with ease, accessing areas that may be difficult for human responders to reach. This adaptability ensures comprehensive fire suppression coverage throughout the facility.

Continuous Monitoring and Real-Time Feedback: Explosion-proof robots continuously monitor the fire situation, providing real-time feedback to the operators and incident commanders. This data allows for timely adjustments to firefighting strategies, ensuring a proactive approach to fire suppression and preventing fires from escalating beyond control.

Conclusion: In the high-stakes world of oil and gas facilities, efficient fire suppression is critical to ensuring the safety of personnel and protecting valuable assets. Explosion-proof firefighting robots offer numerous advantages in this regard, from swift response and targeted fire control to reducing human exposure to hazards and adaptability in challenging terrain. By leveraging the benefits of explosion-proof robots, companies can enhance fire safety measures, minimize potential risks, and maintain the continuity of their operations in the face of fire emergencies.

Thermal Infrared Image Camera

TFT Fire Monitor: 80L/S flow, water/foam dual-purpose, range 80 meters

Gas collection: The collection of six gases around the robot body

Lighting: double LED strong lightAcoustic-optic

Alarm: the robot sends out acoustic-optic alarm under the running state of the robot body

Automatic obstacle avoidance: always detect obstacles in front to avoid collision

Spray cooling: water curtain spray cooling

| Chassis configuration parameters | |||

| Dimension | 1612*910*1427mm | Weight quality | 726kg |

| Max obstacle height | 》220mm | Climbing ability | >70% |

| Direct run deviation volume | 《5.1% | Speed | >1.5m/s |

| Infrared thermal imager | Yes | Braking distance | <0.15m |

| Anti-collision function | yes | Spray cooling device | yes |

| Lighting | yes | Acoustic-optical alarm function | yes |

| Wading depth | 400mm | Water-proof function | IP67, top IP65 |

| Drag water belt ability | 2pcs80water belt 100M | Working time | 5h |

| Remote distance | 1000m | Speed control way | Wireless control |

| Gas collection | O2/CO2/CO/H2S/CH4/NH3 6kinds of toxic and combustible gases | ||

| Fire water cannon configuration parameters | |||

| Working pressure | 1.0MPA | Flow | 80L/s |

| Fire range | Water>85M, foam>80M | Pitching angle | -18~90 degree |

| Rotary | -45 ~ +45 degree | ||

| Control box configuration parameters | |||

| Dimension | 467*366*188mm | Weight | <10kg |

| Display size | 15inch | Working pressure | 24VDC/12VDC |

| Digital transmission frequency | 902-928MHZ | Format | Portable |

| Camera configuration parameters | |||

| Working temperature | DC12V | Signal system | PAL or webcam |

| Average relative humidity | <95%(+25degree) | Cloud platfrom performance | initial height>1430mm, lift up the rear height>1940mm |

Please don't hesitate to send us message!

Contact us now!!

00001. Firefighting robot

00002. Fire robot

00003. Fire rescue robot

00004. Fire suppression robot

00005. Fire response robot

00006. Fire emergency robot

00007. Fire extinguishing robot

00008. Fire safety robot

00009. Fire service robot

00010. Firefighter robot